Kest Technology

Sanitary mixers are designed for hygienic and sterile processing, used in industries like pharmaceuticals, food and beverage, and biotech, ensuring product integrity and compliance with stringent sanitary standards.

Precision Mixing Solutions for Hygienic Manufacturing

Kest provides a wide array of durable, precision mixers and tank components for aseptic, reliable pharmaceuticals and food & beverage production.

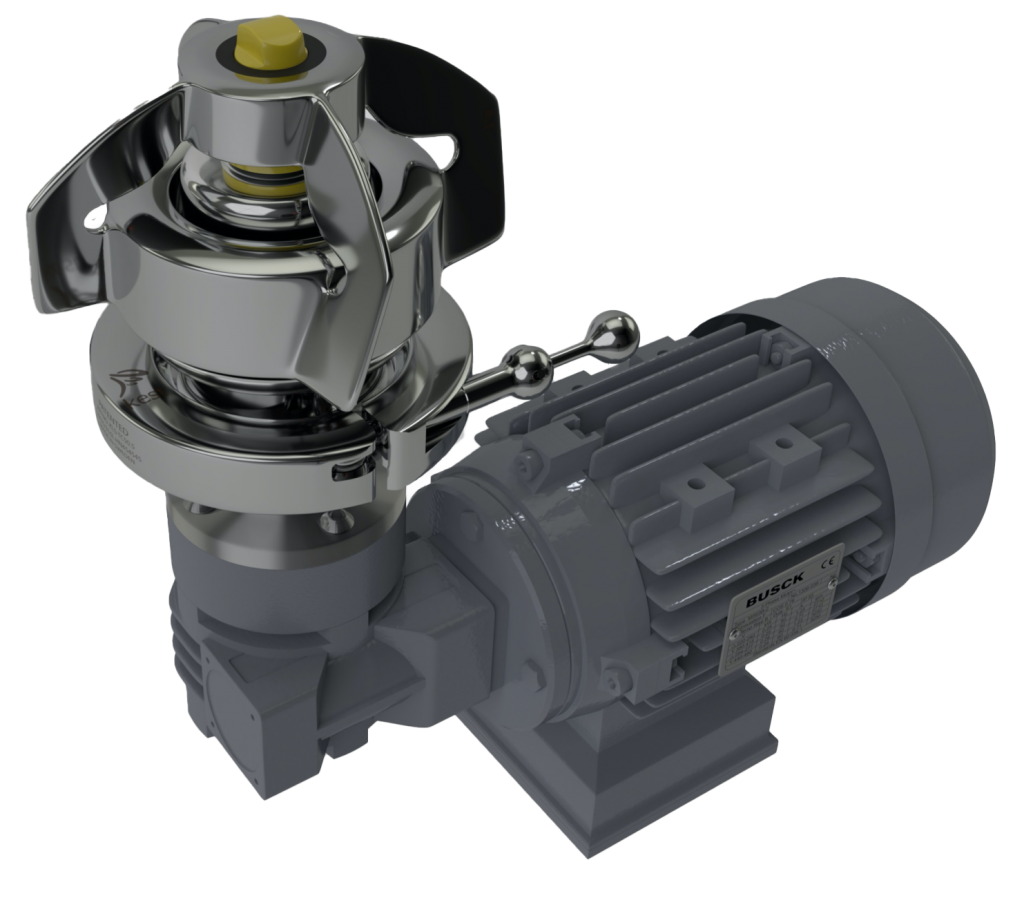

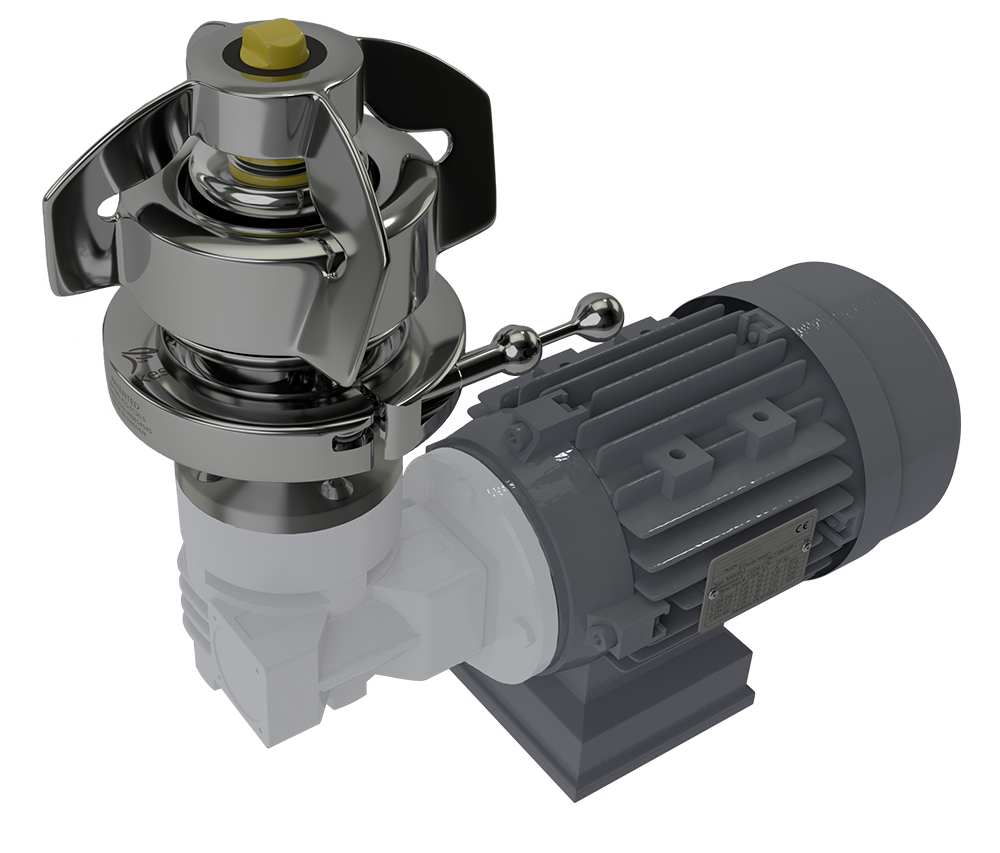

The Kest mixers is a range of magnetic coupled mixers for pharma and aseptic food and beverage applications. The aseptic design is allowing the mixer to be cleaned in place and sterilized in place (CIP/SIP). The tank gets equipped with a tank plate that is welded into the tank, this eliminates any risk of contamination from the outside environment. The placement of the mixer in the bottom of the tank in combination with the bearing design enables for low volume mixing and mixing to the last drop to ensure full product recovery.

The drive unit is equipped with our patented Kest-Lock connection that ensures quick disconnection from the tank plate during maintenance. When you put the drive unit back on the tank plate, the spring closed Kest-Lock helps the operator to hold the drive unit in place when tightening the screw to lock it in place.

Connect with a Hygeniks team member to discuss your sanitary mixing needs!

Our Products Include:

Kest Mixer ProFlow - KMPF

Kest Mixer Small Volume - KMS

Kest Mixer - KM

Kest Mixer ATEX - KM ATEX

Kest Mixer Rapid Motion - RM

Kest Mixer Rapid Motion ATEX - RM ATEX

The Importance of Sanitary Mixing

Sanitary mixing plays an essential role in the combination, uniformity, or stirring of materials while adhering to stringent sanitary and hygienic guidelines. Consequently, it is a vital procedure in the manufacturing of food, pharmaceuticals, cosmetics, and other goods that necessitate exceptional safety and cleanliness. The objective of sanitary mixing is to generate consumable or usable products that are of superior quality, safeguarded, and hygienic.

Additionally, employing a mixer that satisfies rigorous sanitary standards helps prevent the proliferation of harmful bacteria and other microorganisms that can induce illness or spoilage. Consequently, manufacturers can fabricate products that are secure, of high quality, and compliant with regulatory requirements.

When choosing a sanitary mixer, manufacturers must contemplate several pivotal factors. First and foremost, they should opt for a mixer composed of materials that resist corrosion, are non-reactive, and can be easily cleaned. Secondly, they should select a mixer specifically designed to minimize the risk of contamination and that is easily cleanable and sanitizable. Finally, the mixer should possess the capability to deliver the necessary mixing performance, such as blending, homogenizing, or agitating.

To summarize, sanitary mixing is a crucial process that guarantees the safety and excellence of products across various industries. By selecting a mixer that fulfills material, hygienic design, and performance standards, manufacturers can produce products that are secure, of high quality, and compliant with regulatory requirements.

Our Trusted Partners

Connect with a Dedicated Hygeniks Representative

Hygeniks has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.