Sanitary Pumps

Optimizing Performance of Sanitary Pumps to Enhance Product Quality and Safety

Responsible for driving positive product yield, pumps are a critical piece of sanitary process equipment in the pharmaceutical processing, beverage manufacturing, food processing and cosmetics manufacturing industries.

All of Hygeniks’ easy-to-clean pumps help ensure hygienic and sterile conditions. We offer a wide range of stainless steel pumps for long-term processing needs as well as disposable, single-use pumps that enable efficient project changeovers.

Each of our pharmaceutical-grade pumps are backed by proper documentation.

Connect with a Hygeniks team member to discuss your sanitary pump needs!

Our Products Include:

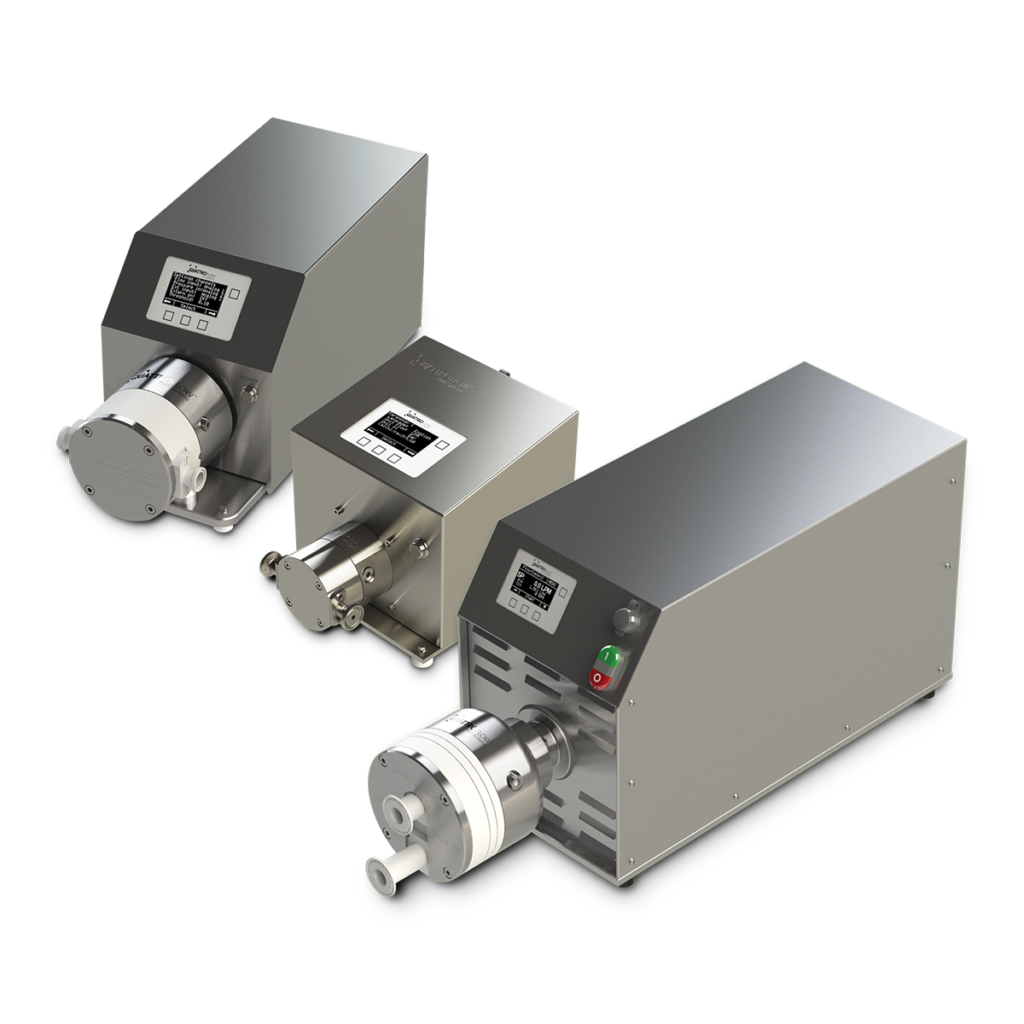

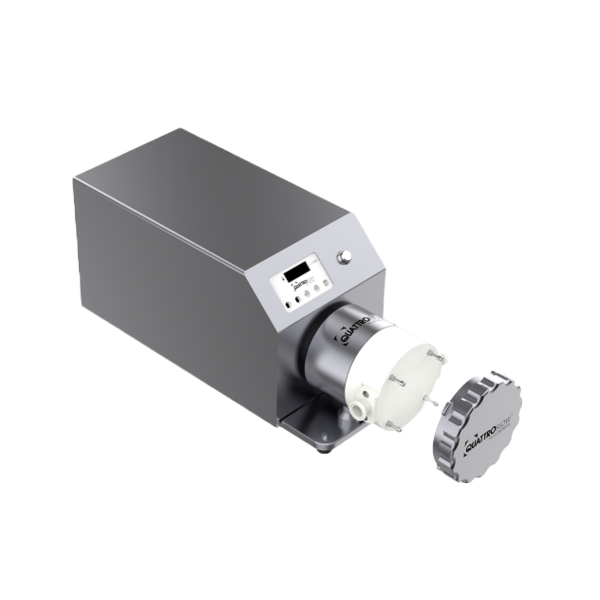

Quaternary Diaphragm Pumps

Single-Use Quaternary Pumps

Q-Control

EZ Set Chamber

& many more!

FEATURED PRODUCT

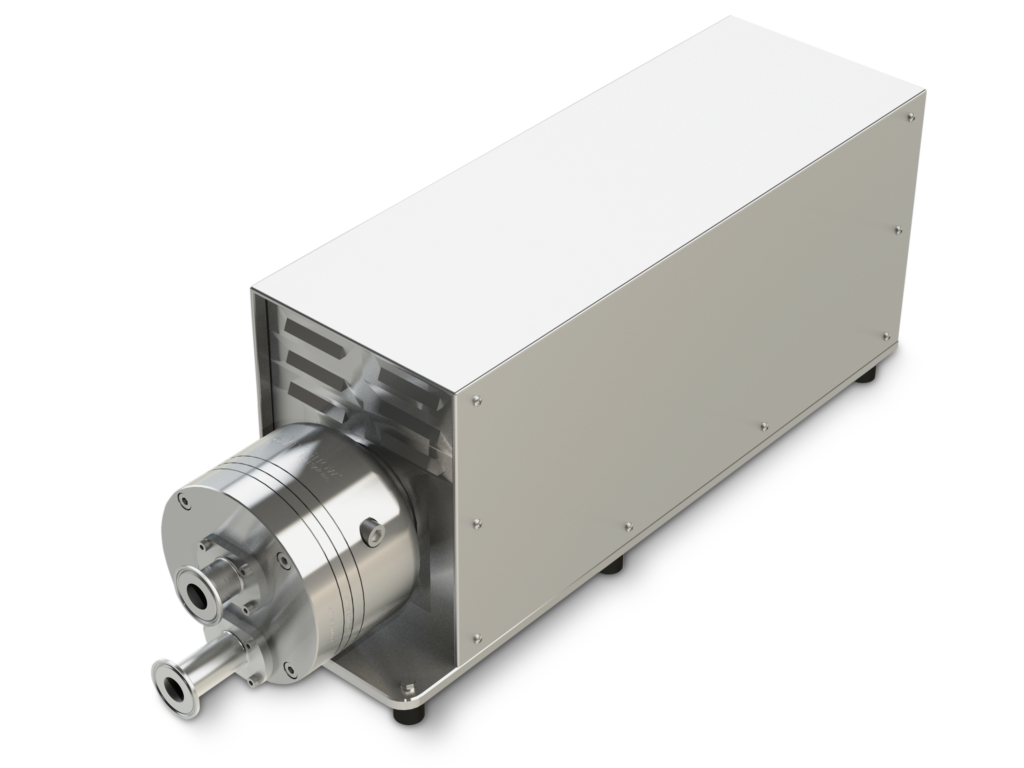

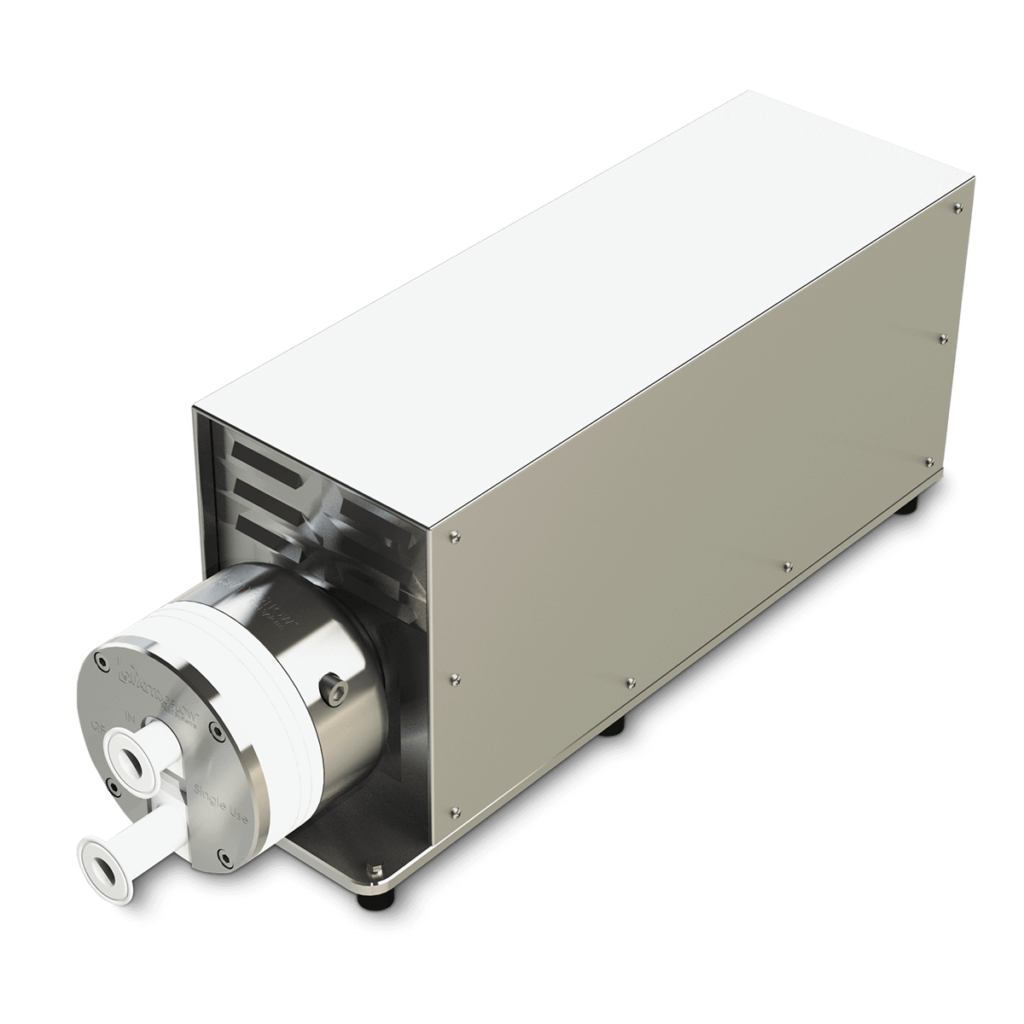

OnePump VersaFlow

FEATURED PRODUCT

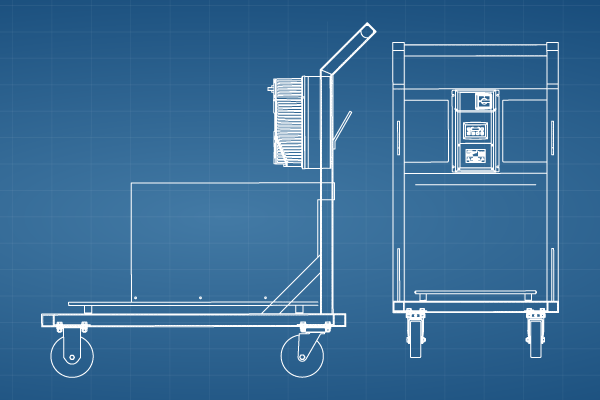

Pump Cart Solutions

Custom Pump Cat Solutions incorporating Quattroflow, Watson-Marlow, Masterflex and other pump brands

AVAILABLE OPTIONS:

- 1/2-5 HP frame mounted motors

- Sperate VFD controls

- Integrated flow, pressure and weight

- Shelf locations: top, bottom, or no shelf

- Wheels: Swivel, fixed, non-marking

- Tubing / hose management

- Power cord wrap

- Custom cart dimensions

OnePump VersaFlow

Optimizing Your Sanitary Pumps

Maintaining optimal performance of sanitary pumps is crucial for upholding hygienic conditions and guaranteeing the quality and safety of products.

To achieve this, it is vital to conduct regular maintenance activities such as examining and replacing worn or damaged parts, lubricating moving components, and inspecting for leaks or other potential problems.

Additionally, proper cleaning procedures are essential to preserve sanitary conditions and prevent contamination. While sanitary pumps are designed for easy cleaning, it is important to adhere to correct cleaning protocols and use suitable cleaning agents to prevent pump damage or the presence of residue that could contaminate the product.

Monitoring pump performance aids in the early detection of issues before they escalate. This involves checking for unusual noises or vibrations, monitoring flow rates and pressures, and conducting regular inspections of seals and other components.

By adhering to these performance optimization guidelines, you can ensure that your sanitary pump operates at its highest performance level, thereby delivering superior product quality and safety.

Our Trusted Partners

Connect with a Dedicated Hygeniks Representative

Hygeniks has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.